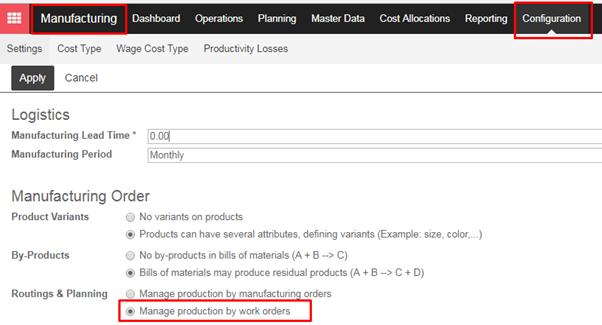

To use work center and routings, you will need to enable Manage production by work orders from Manufacturing -‣ Configuration -‣ Settings

- When manufacturing with work centers and routings, each work order is scheduled individually. Manufacturing using routings can be broken down into several steps. When configuring you bill of material, you will need to add a routing defining the component work orders

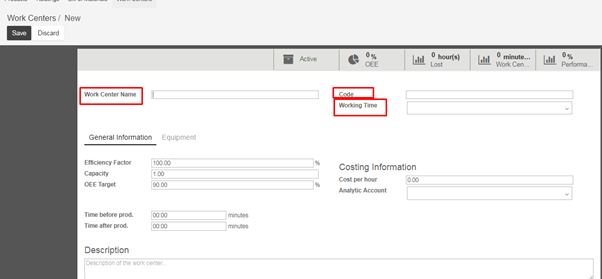

→ How to create a work center

- Go to Manufacturing module-‣ Master data -‣ Work centers then click on Create button to establish a work center

A work center can be a set of workers or machines which are used for task assignment as well as capacity and planning forecast. Fill in the work center name, code and select working time of the work centers -‣ then click Save

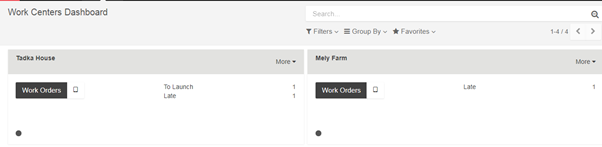

- Work center will be available on the Manufacturing dashboard

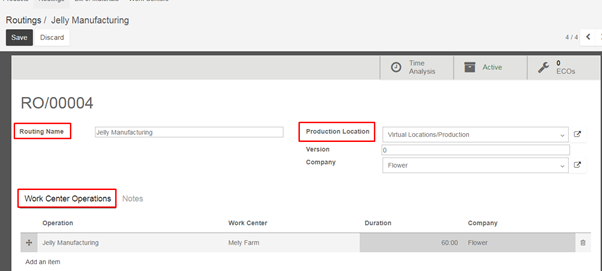

→ How to create a routing

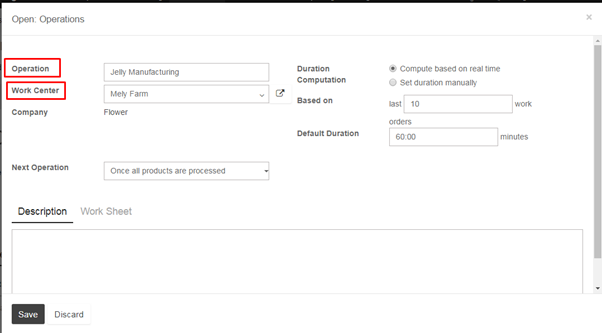

- A routings defines a series of operations required to manufacture a product and the work center at which each operation is performed

- Go to Manufacturing ‣ Master data ‣ Routings ‣ Select Create for new routings

- Fill in Routing name, select Production location

- In the Work center operations tab, click on Add an item to add the new operation on the assembly line. Each operation is linked to the center. Enter the name in the operation field, select the work center for this operation -‣ then click Save